Graphite electrodes and nipples for the production of electric steel are applied in electric arc furnaces.

The mechanical process begins when the electrodes are cleaned or trimmed. Before impregnation and/or graphitizing, the electrode is freed from baking residues on the circumference and its faces.

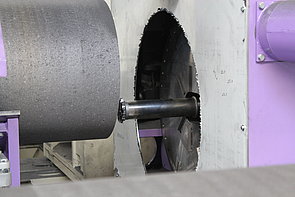

Graphitization is followed by the actual finishing process. This machining is performed on a system with several stations. The number of stations is determined both by the desired production capacity and by the requirements on quality and material testing. The largest fully-automated system comprises ten stations.

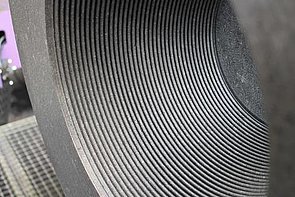

The nipple machining system also consists of several stations. The nipple rod is first sawn to length. This is followed by the various machining stages: centering, rough turning, thread machining, polishing, groove milling, drilling. After these steps comes the quality inspection. How the machining phases are split will depend on the required production capacity and specific customer requirements for measuring and testing.

Other projects in this sector can be designed and built according to specific customer requirements.

The fully automatic systems are run by one operator.