Brick slips

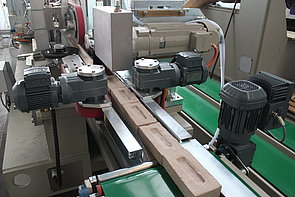

The bricks are deposited either manually or automatically in a row on the conveyor belt in front of the machine. They are aligned automatically and clamped firmly during the sawing process by a pressure unit acting from above. The first quarter brick is sawn to size with two saws from above and below. It then slides onto a discharge conveyor that transports it back to the operator. Next, the brick is automatically aligned to the opposite side against a stop while a second quarter brick is sawn to size and likewise returned to the operator. The system has a high feed rate because the cutting is divided between two units and the bricks are guided and clamped securely during the sawing process. This also ensures that the saw blades have a longer service life.

The new Wassmer single-face brick slip saw

By reason of several customer inquiries Wassmer developed a small single face brick slip saw.

The Wassmer DFS-04R-L is the ideal machine for small firms who cannot exploit the potential of the two face machine and for brick slip producers from extruded bricks showing only one useful face.

In doing so the small single face brick slip saw uses the proven technology of the big Wassmer brick slip saws that are successfully in use for many years in the factories of well-known producers:

- Double arbor sawing technique

- Central cooling water feeding

- Clamping of the bricks through a pressing device and support of the brick slips until the sawing process is terminated.

Advantages:

- fast downfeed speed

- no chipping at the lower brick slip edge

- no broken corners

- clean brick slips

- smaller standard saw blades

This machine is sturdy built, settings of brick slip thickness and saw blade adjustments can be done fast and precisely by hand through handles.

User and maintenance friendliness are self-evident at Wassmer

Are you curious and having questions regarding this novelty? Contact us for more !

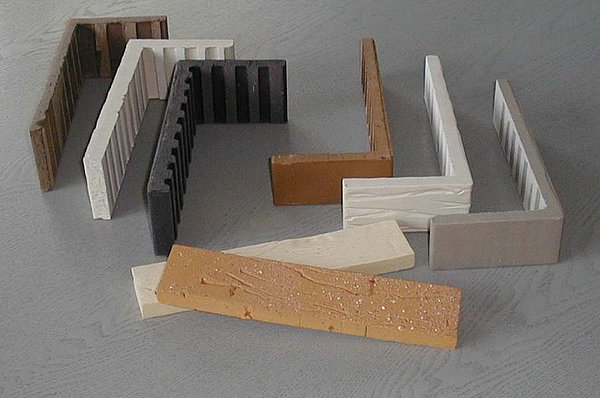

Angle quarter bricks

The bricks are deposited on a conveyor belt either manually or automatically and pushed automatically into two sawing stations of the system. At these stations the brick is clamped automatically on the short and long side. At these two sawing stations two horizontal and two vertical saw blades then cut out the angle quarter brick. The remnants fall into a container and the finished angle quarter brick is gently deposited on a conveyor belt and transported back to the operator. Scrap page is reduced considerably because the angle quarter brick to be sawn is clamped firmly.